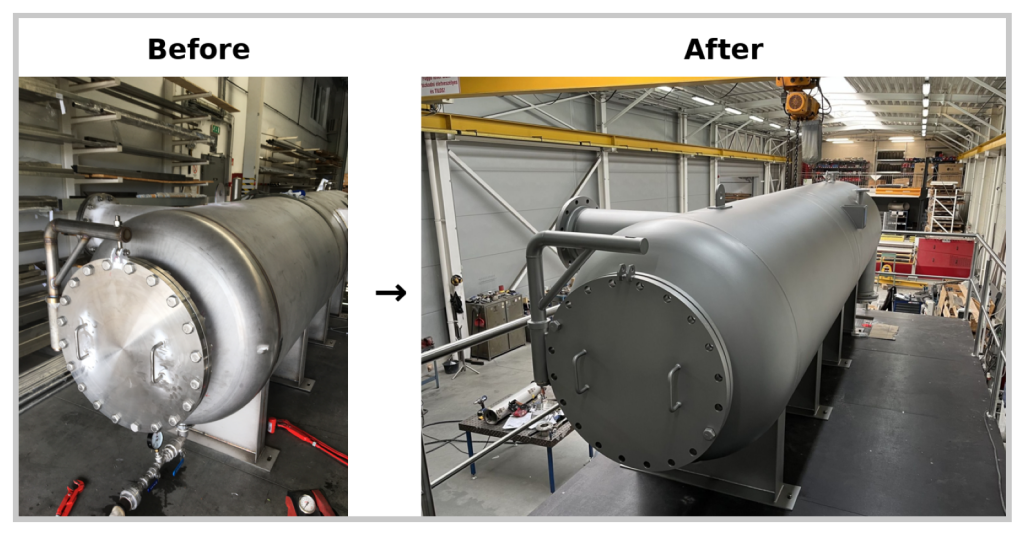

Glass bead blasting is one of the most commonly applied surface treatments for stainless steel components, as it delivers both aesthetic and functional benefits. The process uses small, spherical glass beads that are blasted onto the metal surface at high pressure. This does not remove material from the surface but rather smooths and unifies it, creating a uniform, matte, silk-like finish.

Why use it?

-

Creates a consistent matte surface – ideal for both design and hygiene-critical environments.

-

Relieves surface tension – minimizes the risk of microcracks that may develop during fabrication.

-

Improves corrosion resistance – by removing impurities and supporting the formation of a passive protective layer.

-

Perfect for post-weld treatment – delivers clean, visually uniform results even on welded areas.

Where and how do we apply it?

At GYGV, we operate a dedicated, spacious bead blasting room measuring 8 x 3 x 3.5 meters, which allows us to treat large industrial units such as equipment housings, storage tanks, and pressure vessels safely and efficiently.

We also offer precise and efficient treatment for smaller components in high volumes, such as industrial fittings, custom parts, and stainless accessories.

Regular applications include:

-

Stainless industrial components

-

Machine housings and covers

-

Pressure vessels

-

Storage tanks

-

Process system fittings

-

And a wide range of other custom stainless steel solutions