Electropolishing is a specialized electrochemical process that removes a microscopically thin layer from the surface of stainless steel. This technique not only produces a visually striking, bright finish but also offers numerous technological advantages.

What is Electropolishing?

The workpiece is immersed in an electrolytic bath, and a controlled electric current is applied to remove the topmost uneven micro-layer of the metal. This results in a smooth, bright, and seamless surface that is easy to clean—all achieved without material loss or mechanical damage.

Why is it Beneficial for Stainless Steel?

Mirror-Smooth, Bright Finish: Provides a premium appearance, repels dust, and is easy to clean.

-

-

Excellent Hygiene: The smooth, crack-free surface prevents the accumulation of contaminants and bacteria.

-

Enhanced Corrosion Resistance: Removes residual contaminants from manufacturing and renews the passive layer.

-

Precise Contour Preservation: Does not deform the workpiece, ensuring uniform surfaces even on complex geometries.

-

Where is it Applied?

Electropolishing is an ideal choice for:

-

-

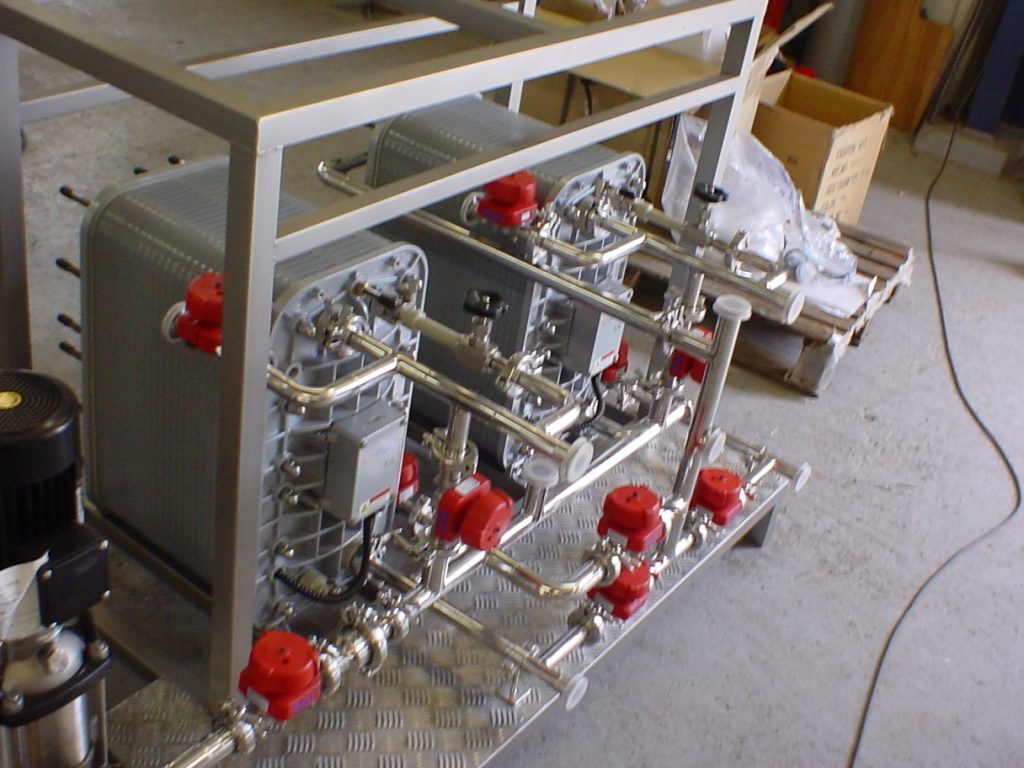

Food and pharmaceutical industry equipment

-

Critical stainless steel components

-

Internal surfaces of tanks, pipelines, and valves

-

Products requiring design excellence and premium finishes

-

Have questions or require similar surface treatment services?

Contact us, and we’ll help you find the best solution!